Ammonia Desorption and Absorption Technology

Key words: Multi-effect evaporation | distillation | resin adsorption

Classification:

Product Description

To meet customer demands for low investment in ammonia nitrogen wastewater design, low operating costs, small footprint, high treatment efficiency, and no secondary pollution, our technical team has developed an efficient ammonia absorption resource recovery process.

Compared to the above technologies, our newly developed efficient ammonia absorption resource recovery process utilizes the pressure changes generated by high-speed fluid ejected from a vacuum ejector to fully decompose or absorb the overflow substances in the material, achieving deammoniation and ammonia production in a short time. This process has a high degree of integration, with the wastewater deammoniation and ammonia production processes concentrated in one module, occupying less space, facilitating transportation, and simplifying on-site installation work. The automation level is high, and after one-click operation, no on-site personnel supervision is required, with a system deammoniation rate exceeding 90%.

Vacuum Ejector Absorption Principle Diagram

| Vacuum ejector absorption: Utilizing a liquid medium provided by a centrifugal pump at a certain pressure, the pressure energy is converted into high-speed kinetic energy through a nozzle, creating a vacuum in the suction chamber that draws in gas or liquid from the suction port into the throat and into the diffusion tube to form a high-speed mixed flow. The pressure changes caused by the velocity fluctuations of the liquid create compressive forces that lead to bubble splitting, resulting in fine, well-dispersed bubbles: the high-speed airflow also easily shatters droplets, creating significant turbulent performance with a large contact area, thereby greatly enhancing mass transfer effects. |

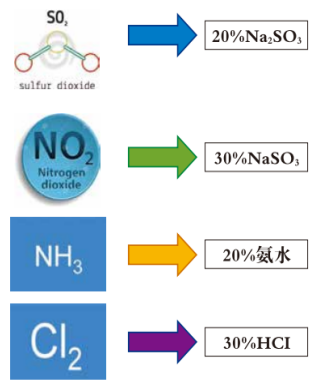

This process is applicable to gases such as SO2, HCL, NH3, NO2, H2S, and is widely used with strong adaptability.

| Process Advantages(1) Inorganic waste gas is converted into acids, bases, and salts for resource utilization; (2) Vacuum ejector absorption, high-speed gas-liquid mixing, good absorption effect; (3) Adjustable vacuum degree at the suction inlet, used for tail gas treatment in reaction vessels, can remove residual gases in reactants, improving reaction efficiency and product recovery rate; (4) Series multi-stage packed absorption tower, good treatment effect, high recovery concentration; (5) Integrated device, small footprint, high degree of integration; (6) Can be used for segmented absorption of Cl2+SO2 mixed gases; (7) Online detection of acid/base concentration, automatic feeding/discharging, unattended operation. |

Related process

Online message

If you have any need, please feel free to contact us.

Phone:+86-15995082506(WeChat with the same number)

E-mail:jsyjhb001@163.com

Address: No.61, Lvshu East Road, Changzhou City, Jiangsu Province

Concerned about the public.

Copyright©2024 Jiangsu Yijian Environmental Protection Technology Co., Ltd.