Multi-effect evaporation technology

Key words: Multi-effect evaporation | distillation | resin adsorption

Classification:

Product Description

Multi-effect evaporation

| Multi-effect evaporation is a series evaporation device that uses the secondary steam from the previous effect as the heating steam for the next effect. It is suitable for situations where the price of steam is low and the boiling point of the evaporated material is relatively high. To address issues such as the large number of devices, high costs, and long supply cycles in conventional multi-effect evaporation systems, Jiangsu Yijian Environmental Protection adopts standardized and modular design, complete sets of electromechanical equipment and instruments, and batch preparation of non-standard equipment, which reduces project investment costs and shortens supply cycles. To tackle the high energy consumption, complex operation, and easy blockage of conventional multi-effect evaporation systems, Jiangsu Yijian Environmental Protection employs methods such as multi-point gas extraction, internal circulation of pipelines, steam backflushing, key node PID control, and PLC/DCS self-adaptation to reduce system energy consumption, alleviate blockage, and achieve fully automatic operation of the system. |  |

Comparison of different evaporation methods

| Evaporation methods | Single-effect evaporator | Three-effect evaporator | MVR evaporator |

| Operating cost | 1.05 tons of steam per ton of water, electricity consumption 20kW.h | 0.4 tons of steam per ton of water, electricity consumption 30kW.h | 0.03 tons of steam per ton of water, electricity consumption 70kW.h |

| Investment cost | Low | Medium | High |

| Applicable occasions | Small processing volume, poor wastewater quality, high viscosity | Large processing volume, high salinity water, higher boiling point | Limited steam supply, high salinity water, not high boiling point |

| Energy method | Uses steam heating, requires a steam pipeline network | Uses steam heating, requires a steam pipeline network | Can use electricity, with a small amount of supplementary steam, fully closed-loop system |

| Degree of automation | Semi-automatic | Fully automatic operation, continuous evaporation | Fully automatic operation, continuous evaporation |

| Stability | Good | Good | Good |

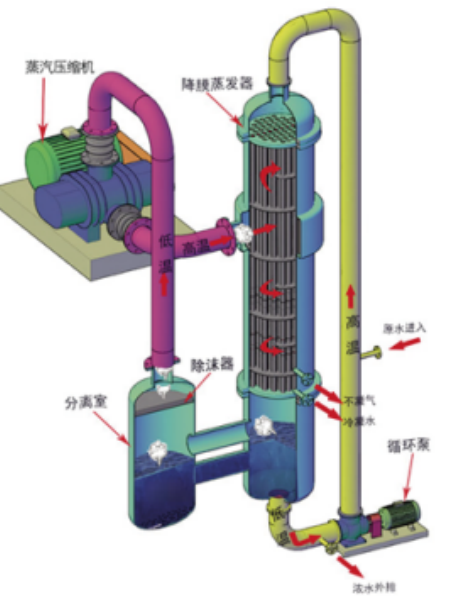

Falling film evaporator

In the evaporator, the liquid and steam flow downward. The feed liquid is preheated to boiling temperature, and a uniform liquid film is formed by the liquid distribution device at the top entering the heating tube, where partial evaporation occurs. The generated secondary steam enters the separator from the bottom of the evaporator. The separated secondary steam is sent to the heating chamber of the evaporator as heating steam after being worked on by the steam compressor. Since the falling film evaporator evaporates inside the tube, its heat transfer rate is higher than that of other types of evaporators. Additionally, falling film evaporation does not have liquid column pressure. The heat transfer temperature is significantly higher than that of other types of evaporators, thus achieving good heat transfer effects, with minimal initial investment, making it the preferred evaporation type for customers. |  |

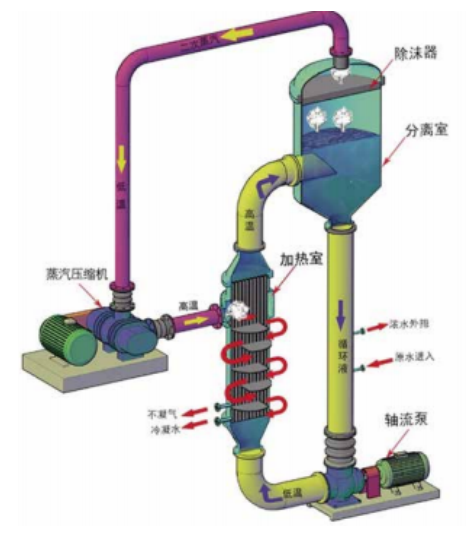

Forced circulation evaporator

The forced circulation evaporator uses external power (forced circulation pump) to send the descending solution and part of the raw material liquid to the heating chamber, greatly accelerating the circulation speed. When the circulating liquid flows through the heat exchanger, it is heated, and then it flashes evaporates when the pressure is reduced in the separator, cooling the liquid to the boiling point temperature at the corresponding pressure. The secondary steam separated by the separator is sent to the heating chamber of the evaporator as heating steam after being worked on by the steam compressor, while the heating steam itself condenses into water. The forced circulation evaporator is particularly suitable for materials that are prone to wall sticking, scaling, and have high viscosity. |  |

Related process

Online message

If you have any need, please feel free to contact us.

Phone:+86-15995082506(WeChat with the same number)

E-mail:jsyjhb001@163.com

Address: No.61, Lvshu East Road, Changzhou City, Jiangsu Province

Concerned about the public.

Copyright©2024 Jiangsu Yijian Environmental Protection Technology Co., Ltd.